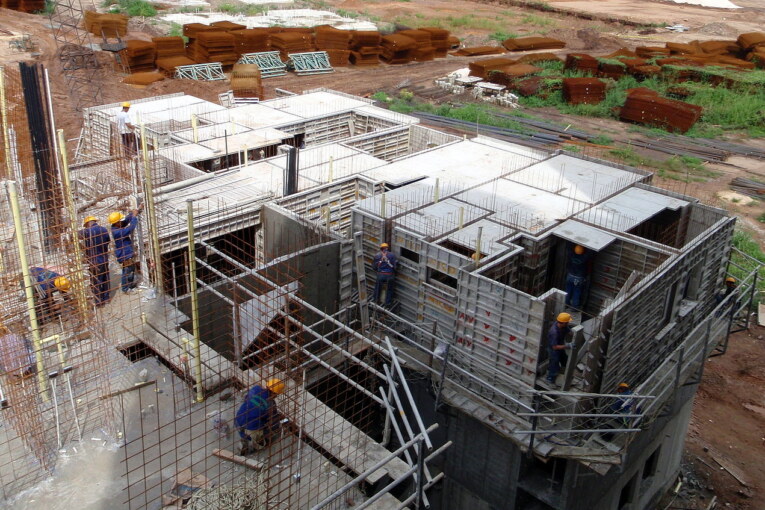

Formwork is a die or a mould including all supporting structures, used to shape and support the concrete until it attains sufficient strength to carry its own weight. It should be capable of carrying all imposed dead and live loads apart from its own weight.

There are many based on its material, their use and the type of structural members. They can be named based on that. However, core functioning of the formwork remains the same.

Types of Formwork (Shuttering) Based on Structural Member:

Formworks are used in construction of reinforced concrete foundations, columns, slabs, walls etc., and these are named as follows:

- Footing Forms – Formworks for foundation

- Column Forms – Formwork for RCC Column construction

- Wall Forms – Formwork for RCC wall construction

- Floor Forms – Formwork for construction of RCC Slabs

Footing Forms – Formworks for Foundation

The first step for any concrete construction starts with the construction of foundation. Foundation can be for columns or walls. So, based on type of structural member, the shape and size of footing are designed. Thus formwork size and shape depends on the type and dimension of the footing.

Components of Footing Formwork – For Shallow Footing – Continuous Footing Formwork

Column Forms – Formwork for RCC Column construction

Reinforced concrete column forms are subjected to lateral pressure because of their small cross section, large heights and relatively high rates of concrete placement. Thus It is necessary to provide tight joints and strong tie support to the formwork.

As the sizes of concrete column increases, the stiffness of the formwork must be increased by either increasing thickness of sheathing or vertical stiffeners must be added to prevent sheathing deflection.

Formwork for wall construction are subjected to relatively lower lateral pressure than column forms due to their large cross-sectional area.

The components of wall forms are:

- Panel sheathing – It is used to shape the wall and retain the concrete until it sets.

- Studs – to support the sheathing or Wales by forming a framework to keep the forms aligned and support the studs.

- Braces – It is used to prevent deflection of forms under lateral pressure and keep the formwork erect.

- Ties and spreaders – These are used to hold the sides of the forms at the correct spacing.

Floor Forms – Formwork for construction of RCC Slabs

Formwork for reinforced concrete slabs depends on the type of slabs to be constructed. The floor slabs can be structural slabs supported on a steel or concrete structural frame, or slab-on-grade.

The design of formwork varies with the type of slab.

Structural Slab Formwork assembly is carried out as follows:

- Positioning of the girder or beam form at the bottom.

- Girder side forms overlaps the bottom form and rests on the shore heads and the sides of the column form.

- Side forms is held in place by ledger strips nailed to the shore heads with double-headed nails.

- Larger girders should have the side forms vertically stiffened to prevent buckling.

- When constructing the girder and beam forms each part must be removed without disturbing the remainder of the form; strike-off formwork will commence with the beam and girder sides, followed later by the column forms, and finally by the beam and gird bottoms.

Slab-on-Grade Forms are forms for concrete slabs placed on grade. These slab formworks are usually quite simple as concrete is placed on compacted earth or gravel leveled base. Thus no support is required for concrete at the bottom.

Slab-on-Grade Formwork assembly is carried out as follows:

- Plank, plywood, or steel forms are used for forming / supporting the open edges of concrete.

- These forms are held in place by supporting with wooden pegs.

- The reinforcement in slab (if specified in the structural drawing) should be placed on its proper location according to the drawing on chairs, bolsters, and spacers made of either metal or concrete.

- If the slab is to be casted in sections, construction joints must be provided between them, which will transmit shear from one to the other. The details of construction joints should be followed as per structural drawing.