Introduction of Submerged Floating Tunnel

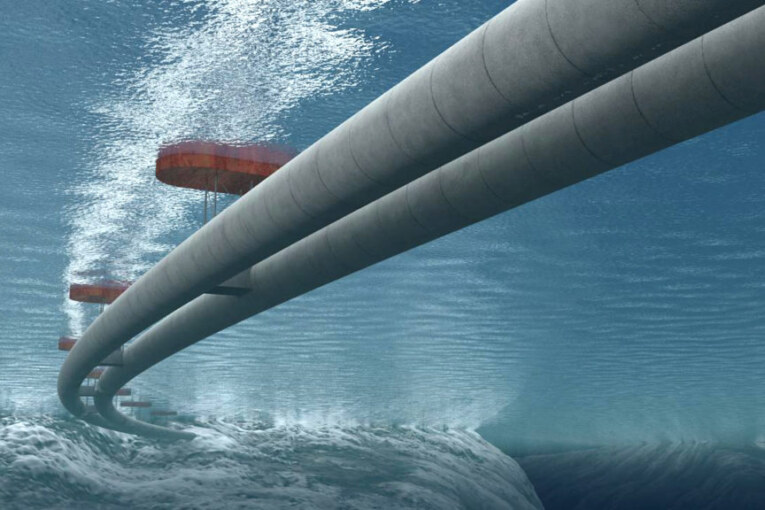

- It is a kind of innovative traffic structure, which is used to cross sea, large lakes or deep rivers.

- It generally consists of tunnel tube suspended in water, anchor cables fixing displacement of tunnel, deep water foundations.

- Submerged Floating Tunnel (SFT), is also known as Archimedes Bridge.

Need of Submerged Floating Tunnel

- A “SFT’ is considered when the depth of the water body is too deep so that no tunnel or any solid body could sustain the pressure acting on it at such a deep level.

- In that case the tunnel is placed such as about 50-60m from the sea level.

Concept of Submerged Floating Tunnel

- It is based on “Archimedes Principle”.

- Any object wholly or partially immersed in an fluid, is buoyed up by a force equal to the weight of the fluid displaced by the object.

- Ships, submarines, offshore oil rigs etc. work on this principle.

- Research shows that the buoyancy to weight ratio for the tunnel to float should be less than one and between 0.5 to 0.8.

Material Used

- Aluminium

- Foam

- Concrete

Structural Components used in Submerged Floating Tunnel

SFT consists of the following elements-

- Tubes

- Tethers

- Pontoons

- Shore connections at the ends of the tunnel.

1. Tube

- Provides space for the road and/or railway traffic.

- The tubes may be constructed of steel, concrete or a combination of the two.

- Designed with circular cross-sections, primarily from hydrodynamic reasons. Other shapes as elliptical, polygonal.

- Gives space to traffic in one direction and provide escape possibilities in case of fire.

2. Tethers

- Vertical or inclined fixing the tube to the seabed at certain spacing.

- Gravity anchors on the seabed providing support for the tethers.

- Vertical tethers gives vertical stiffness, but virtually no horizontal stiffness. In order to also get horizontal stiffness the tethers have to be inclined.

3. Pontoons

- Pontoons are mounted on top tunnel and “anchoring” it to the sea surface.

- Pontoons penetrating the water surface will add vertical stiffness to the system, but they will not add anything to the horizontal stiffness.

- Other measures then have to be added to give sufficient horizontal strength and stiffness.

4. Shore Connections

- The connections of the tube to the shore require appropriate interface elements to couple the flexible water tube with the much more rigid tunnel bored in the ground.

- This joint should be able to restrain tube movements, without any unsustainable increase in stresses.

Construction Procedure

1. Precasting

- Huge tunnel sections are constructed on dry dock.

- The procedure consists same as that of precast construction.

- The panels are transported to their respective places.

2. Joints

- After the submersion of different panels in water they are connected with one another by using the rubber gasket.

- Procedure incudes trapping of water between the joints and then removing it afterwards.

3. Foundation

- This is incase of tethers.

- The application consists same as that of in caisson foundation.

- A hollow chamber is penetrated down the sea bed as shown which evacuates the water trapped inside it by a valve present on its top surface.

4. Anchoring of Cables

- The cables are anchored to the floating tunnel which will avoid its movement and will place it firmly in alignment.

- This operation can be carried out by divers.

Advantages of Submerged Floating Tunnel

- Allows construction of tunnel in extremely deep water, where conventional bridges or tunnels are technically difficult or prohibitively expensive.

- Any type of cross sectional area can be provided since being prefabricated.

- No obstruction to navigational routes as compared to conventional bridges since all of the tunnel being placed underwater.

- Construction activities has less harmful effects on aquatic life.

- Vehicular emission can be collected at one end of the tunnel thus reducing the air pollution.

- No harmful environmental effects such as fog or storm since the whole structure is covered and is present inside the water.

Disadvantages of Submerged Floating Tunnel

- Immersed tunnels are often partly exposed on the river/seabed, risking a sunken ship/anchor strike.

- Direct contact with water necessitates careful water proofing design around the joints.

- The segmental approach requires careful design of the connections, where longitudinal effects and forces must be transferred across.

- Environmental impact of tube and underwater embankment on existing channel/sea bed.