Introduction

- Insulated concrete forms are rigid plastic foam forms that hold concrete in place during curing and remain in place during curing and remain in place afterwards to serve as thermal insulation for concrete walls.

- Homes being built with ICFs have the insulation built into the walls as part of the surface.

- These systems create walls that have a high thermal resistance.

- They also provide a backing for drywall on the inside, as well as stucco, siding, or brick for the outside.

- Very strong structurally, they are an ideal choice for areas that are prone to wildfires, hurricanes, and tornadoes.

- Excellent insulation qualities.

- Easy to build radius walls, which are problematic with conventional wood framing.

- Virtually no worksite cutting, which minimizes waste. This saves money and is a green building practice.

- Quick and efficient to go up because of the linear and streamlined process, from design to finish.

What are Concrete Forms??

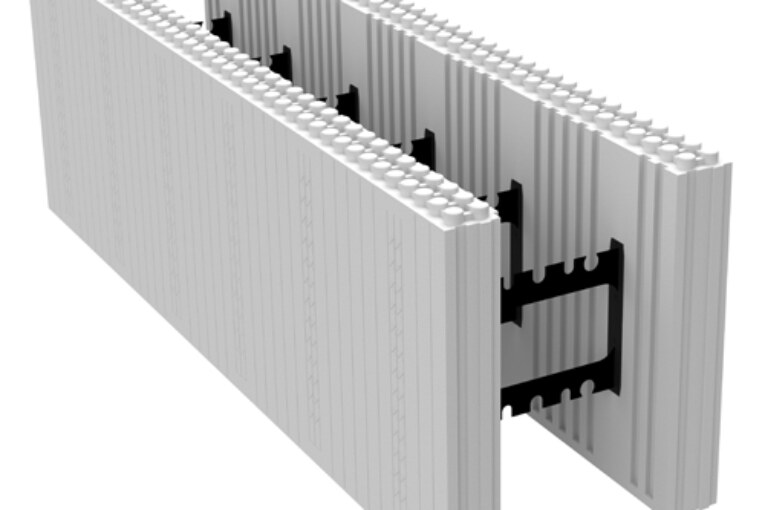

- Basically, insulated concrete forms are construction panels made from expanded polystyrene insulation. These panels are stacked to help build the walls and foundation of your structure.

- Rebar is added for stability, then concrete is poured in to finish it off. Builders can use the ICF process in houses, hotels, townhomes, churches and many other types of structures.

- Insulating concrete forms are basically panels made from expanded polystyrene insulation material. Each concrete form is held in place by plastic bridging and they are stacked to build the wall or foundation.

Why is Insulated Concrete Forms more efficient??

Using concrete forms to create walls and foundations is considered more efficient by many builders, because they snap into place easily and combine five different steps into one. ICF construction provides:

- Insulation

- Structure

- Sound barrier

- Vapor and air barrier

- Fastening strips

The Insulated Concrete Forms Process

- The ICF process begins with the concrete form, or panel. The panels have cut lines on either side, making it easier to cut them to size when the job requires it.

- Steel bracing is put in place in an effort to keep the walls straight and plumb once each concrete form is stacked and the process is complete.

- Steel rebar is also used to help reinforce the walls and to keep everything stable in the case of an earthquake or other natural event.

- A concrete pump or crane and bucket is used to pump concrete into the reinforced wall. The nature of the panels and the concrete help to increase the strength of the concrete by up to 25%.

Benefits of Insulated Concrete Forms

- Environmentally friendly

- Effective sound barrier

- Improved strength and durability

- Improved interior heat retention

- Reduced energy bills

- Cooler interior when it’s hot outside.

Construction strength

- If you live in an area where high winds, earthquake or heavy snow are factors, the strength of concrete forms will provide you with important benefits.

- Insulated concrete forms will increase the overall stability of the structure, which is a must for anyone who lives in areas of extreme weather. A stronger house means fewer repairs and added safety for those inside.

Types of Insulated Concrete Forms

- A flat system yields a continuous thickness of concrete, like a conventionally poured wall.

- A grid system creates walls using a waffle pattern. The concrete is thicker at some points than others.

- A post-and-beam system consists of discrete horizontal and vertical columns of concrete, which are completely encapsulated in foam insulation.

Advantages of Insulated Concrete Forms

- Significant energy savings.

- Severe weather resistance.

- Lower insurance premiums.

- Faster construction time.

- Insect resistant.

- Significant exterior noise reduction.

- Four times the fire resistance of wood-framed homes.

- Environmentally friendly.

Disadvantages of Insulated Concrete Forms

- Combustible forms must be protected by fire barriers both sides.

- Mass of concrete is isolated from building interior.

- Thicker walls reduce floor space.

- Toxic gases in fires.

- Blowouts and other construction issues.